Debunking Myths: The Truth About Diesel and Lubricant Efficacy in Heavy Industries

Understanding Diesel and Lubricant Myths

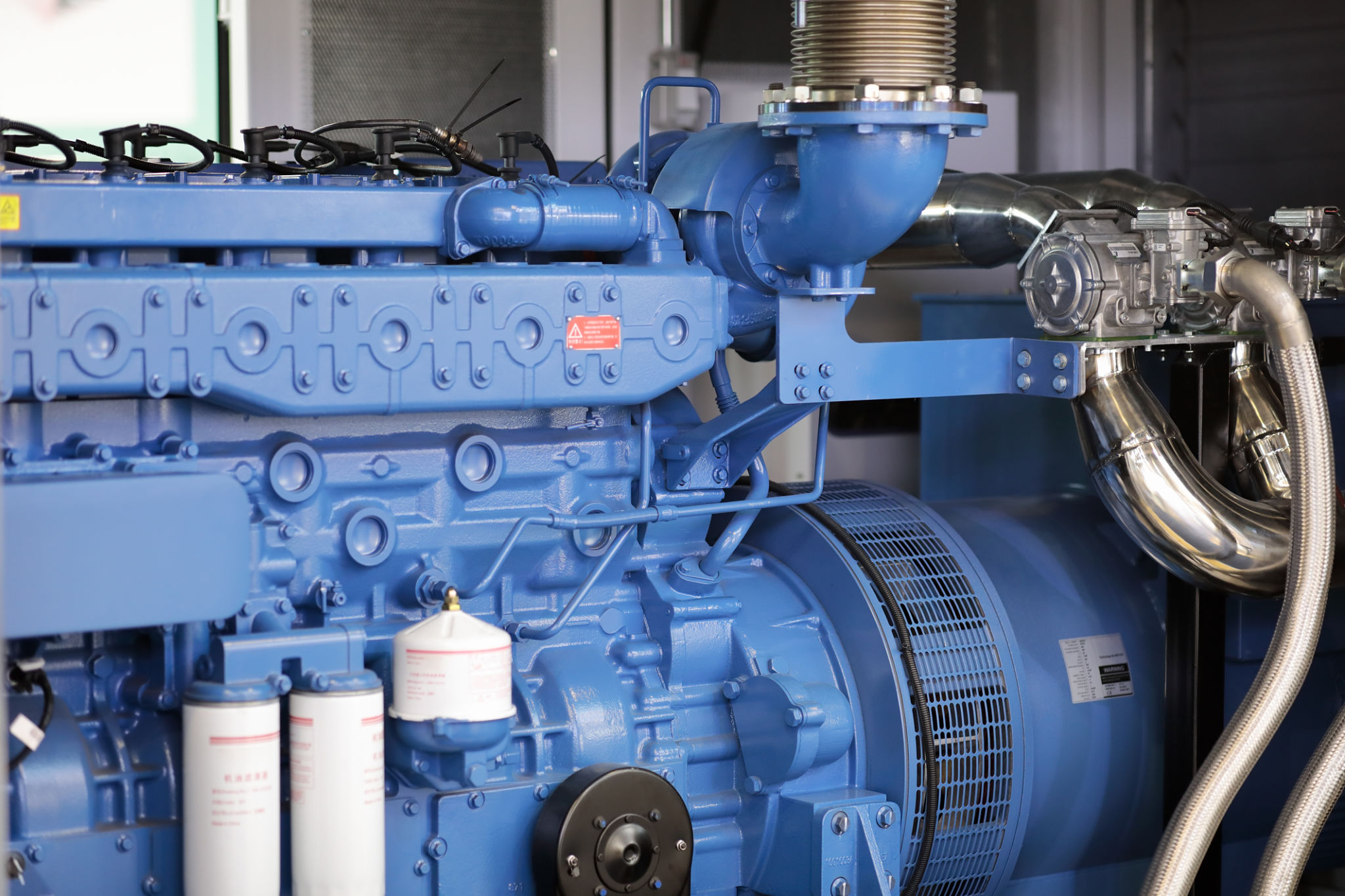

In the world of heavy industries, diesel engines and lubricants are the lifeblood of operations. However, there's no shortage of myths surrounding their efficacy. These misconceptions can lead to costly mistakes, reduced efficiency, and unnecessary environmental impact. Let's explore and debunk some of these myths to ensure your operations run smoothly.

Myth 1: Diesel Engines Are Inefficient

One common myth is that diesel engines are inherently inefficient compared to their gasoline counterparts. In reality, modern diesel engines are designed for high efficiency, particularly in heavy industries that demand durability and power. Innovations in engine design and fuel technology have significantly improved their performance, making them more efficient than ever.

Diesel engines typically have a higher compression ratio than gasoline engines, which allows them to extract more energy from the same amount of fuel. This translates to better fuel economy and lower operational costs over time. It's essential to understand this efficiency to make informed decisions about your machinery investments.

Myth 2: All Lubricants Are the Same

Another misconception is that all lubricants provide the same level of protection and performance. This belief couldn't be further from the truth. Different lubricants are formulated to meet specific requirements based on the machinery's operating conditions, temperature range, and load demands.

Choosing the right lubricant is crucial for maintaining equipment reliability and longevity. High-quality lubricants reduce friction and wear, protect against corrosion, and help in heat dissipation. Investing in the correct lubricant can lead to significant cost savings by minimizing downtime and extending equipment life.

Myth 3: Diesel Engines Are More Polluting

The perception that diesel engines are more polluting than gasoline engines persists despite advancements in emission control technologies. Modern diesel engines are equipped with features like particulate filters and selective catalytic reduction systems that drastically reduce emissions.

Moreover, the introduction of ultra-low sulfur diesel (ULSD) has significantly cut sulfur dioxide emissions, making diesel a cleaner fuel option for heavy industries. It's important to stay current with emission regulations and technological advancements to ensure compliance and sustainability.

Myth 4: Regular Maintenance Is Unnecessary with High-Quality Fuels

Relying solely on high-quality fuels and lubricants does not eliminate the need for regular maintenance. Routine checks and servicing are vital to ensure engine efficiency and longevity. Neglecting maintenance can lead to unexpected breakdowns and costly repairs.

- Regularly inspect fuel filters and replace them when necessary.

- Monitor oil levels and quality to prevent engine damage.

- Ensure proper cooling system operation to avoid overheating.

The Importance of Educated Choices

Debunking these myths highlights the importance of making educated choices about diesel engines and lubricants in heavy industries. By understanding the facts, businesses can optimize their operations for better performance, cost savings, and environmental responsibility.

Ultimately, staying informed about technological advancements and industry best practices empowers decision-makers to invest wisely, ensuring a sustainable future for their operations. Embrace these truths to enhance your company's productivity and sustainability in the ever-evolving industrial landscape.